How Do CCD Web Guiding Sensors Ensure Unmatched Precision in Web Alignment

Date:

2025-01-16

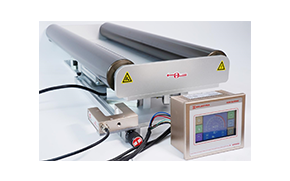

CCD web guiding sensors bring advanced optical technology to the world of material alignment, providing unparalleled precision in guiding webs. These sensors use charged-coupled device (CCD) technology to capture detailed images of the material’s position, enabling precise corrections to be made. This high level of accuracy is essential in industries such as electronics, printing, and packaging, where even the smallest misalignment can result in defective products.

CCD sensors are particularly effective in detecting the edges of materials, even those with complex textures or patterns. Their ability to operate in various lighting conditions further enhances their versatility. By providing high-resolution feedback on web position, CCD sensors ensure that material alignment is maintained consistently, even during high-speed operations.

The use of CCD web guiding sensors not only improves product quality but also reduces material waste and machine downtime. By ensuring that the web stays on track, these sensors contribute to a smoother production process, enhancing overall efficiency and reducing costs.

Related information