Why Are Ultrasonic Web Guiding Sensors Crucial for Material Alignment

Date:

2025-01-16

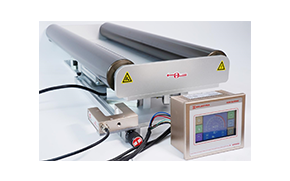

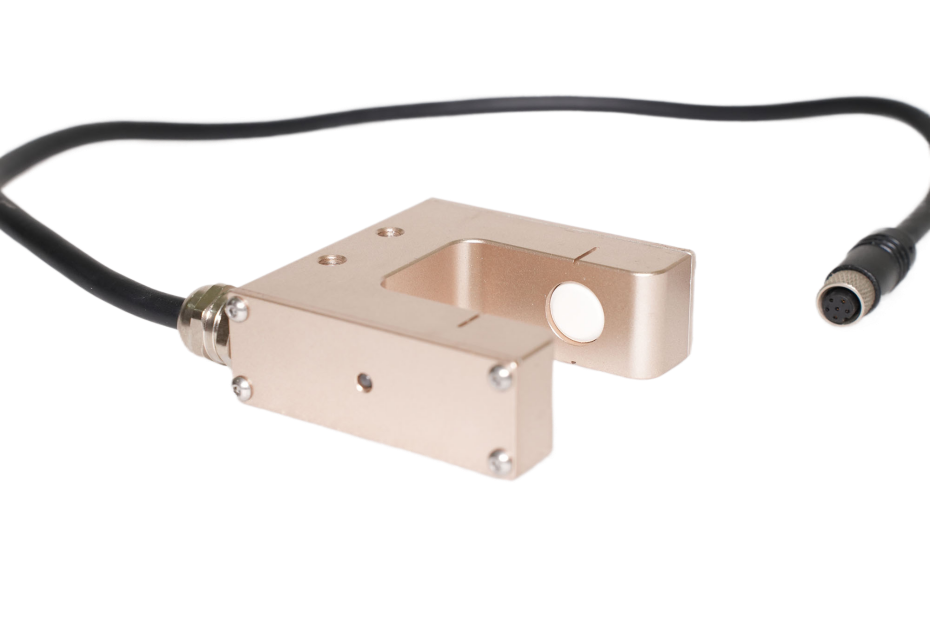

Customized Ultrasonic web guiding sensors are critical in ensuring accurate material alignment during the production process. These sensors use ultrasonic waves to detect the position of the material’s edges, enabling precise control of web alignment. This non-contact method is especially beneficial in handling delicate materials such as films, paper, or textiles, where traditional sensors might cause damage or wear.

The main advantage of ultrasonic sensors lies in their ability to detect a wide range of materials, regardless of transparency, color, or texture. This makes them ideal for applications where other sensor technologies might struggle. In industries like packaging, converting, and printing, where precision is key, ultrasonic sensors offer high reliability and performance.

By integrating customized ultrasonic web guiding sensors into production lines, manufacturers can significantly reduce material waste, enhance product quality, and maintain high operational efficiency. The non-invasive nature of these sensors ensures that they work seamlessly in various environments, providing long-term reliability and accuracy.

Related information