Revolutionizing Automation: How Edge Position Control Systems Enhance Precision

Date:

2025-01-31

Revolutionizing Automation: How Edge Position Control Systems Enhance Precision

Table of Contents

- 1. Introduction to Edge Position Control Systems

- 2. Understanding Edge Position Control

- 3. Components of Edge Position Control Systems

- 4. Applications in Various Industries

- 5. Benefits of Edge Position Control Systems

- 6. Challenges and Solutions in Implementation

- 7. Future Trends in Automation and Edge Position Control

- 8. FAQs about Edge Position Control Systems

- 9. Conclusion

1. Introduction to Edge Position Control Systems

In the ever-evolving landscape of automation, **edge position control systems** play a critical role in enhancing precision and efficiency. These systems are designed to accurately manage the positioning of machinery and tools, ensuring that operations are executed with the highest degree of accuracy. The integration of these technologies is revolutionizing how industries operate, reducing waste, and increasing productivity.

2. Understanding Edge Position Control

At its core, edge position control refers to the techniques and technologies that allow systems to maintain precise positioning at the edges of defined parameters. This can involve the use of sensors, control algorithms, and feedback systems that work together to correct any deviations in positioning. When integrated into automation processes, edge position control systems ensure that machinery operates smoothly, minimizing errors and downtime.

2.1 The Mechanism of Edge Position Control

The mechanism behind edge position control involves several key components:

- **Sensors**: Devices that detect the current position of machinery parts.

- **Controllers**: Systems that process sensor data and execute commands to adjust positioning.

- **Feedback Loops**: Systems that continuously monitor performance to ensure accuracy.

2.2 Types of Edge Position Control Systems

There are several types of edge position control systems, including:

- **Closed-Loop Control Systems**: These systems use feedback to adjust operations in real-time.

- **Open-Loop Control Systems**: These operate without feedback and are typically simpler but less precise.

- **Adaptive Control Systems**: These adjust their behavior based on changing conditions.

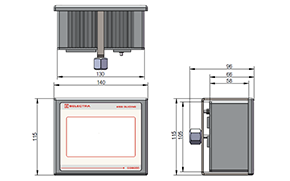

3. Components of Edge Position Control Systems

Understanding the components of edge position control systems is crucial for appreciating their functionality. Each component plays a significant role in ensuring accuracy and efficiency.

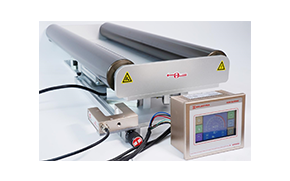

3.1 Sensors

Sensors are the eyes of edge position control systems. They detect the position of moving parts and provide critical data to the controller. Common types of sensors include:

- **Optical Sensors**: Use light to detect position changes.

- **Inductive Sensors**: Utilize electromagnetic fields to determine proximity.

- **Laser Sensors**: Employ laser beams for highly accurate distance measurements.

3.2 Controllers

Controllers act as the brain of the system. They interpret data from the sensors and send commands to the machinery. Depending on the complexity of the system, controllers can range from simple microcontrollers to sophisticated computer systems.

3.3 Actuators

Actuators are the muscles of the system, responsible for moving components as directed by the controller. They can be hydraulic, pneumatic, or electric, depending on the application.

3.4 Feedback Loops

Feedback loops are essential for maintaining accuracy. They continuously monitor the performance of the system and make adjustments as needed, ensuring that the desired position is achieved and maintained.

4. Applications in Various Industries

Edge position control systems are versatile and find applications across various industries, enhancing precision and productivity.

4.1 Manufacturing

In manufacturing, edge position control systems are essential for precision machining processes. They ensure that cutting tools are positioned accurately, reducing waste and improving product quality.

4.2 Robotics

In robotics, these systems enable precise movements, allowing robots to perform complex tasks with high accuracy. This is particularly important in assembly lines where repetitive tasks demand exact positioning.

4.3 Aerospace

In the aerospace industry, precise positioning is critical for safety and performance. Edge position control systems are used in various applications, including the assembly of aircraft components and the operation of flight control surfaces.

4.4 Automotive

Automotive manufacturing relies heavily on edge position control systems for tasks such as welding, painting, and assembly. These systems improve efficiency and ensure that components are manufactured to exact specifications.

4.5 Medical Devices

Medical device manufacturing requires high precision and reliability. Edge position control systems help in the precise assembly of complex medical devices, ensuring they meet stringent quality standards.

5. Benefits of Edge Position Control Systems

The implementation of edge position control systems in automation processes brings numerous benefits, making it an attractive choice for various industries.

5.1 Enhanced Precision

The primary advantage of edge position control systems is the enhanced precision they offer. Accurate positioning minimizes errors, leading to higher quality products.

5.2 Increased Efficiency

By reducing the likelihood of errors, these systems increase operational efficiency. Less time spent on rework or adjustments translates to higher productivity and lower costs.

5.3 Improved Safety

Safety is paramount in any industrial environment. Edge position control systems enhance safety by ensuring that machinery operates within defined parameters, reducing the risk of accidents and injuries.

5.4 Cost Savings

The combination of improved efficiency and reduced waste leads to significant cost savings. Companies can achieve better margins and invest in further innovations.

5.5 Flexibility and Adaptability

Modern edge position control systems are designed to be flexible and adaptable, allowing businesses to modify their operations quickly in response to changing market demands.

6. Challenges and Solutions in Implementation

While the benefits of edge position control systems are significant, challenges can arise during their implementation.

6.1 Technical Complexity

The integration of edge position control systems can be technically complex, requiring specialized knowledge and skills. Companies can overcome this challenge by investing in training and hiring experienced professionals.

6.2 Initial Costs

The upfront costs of implementing advanced control systems can be high. However, businesses should consider the long-term savings and efficiencies that these systems will provide.

6.3 Resistance to Change

Employees may resist changes to established processes. To address this, companies should foster a culture of innovation and involve staff in the transition process.

7. Future Trends in Automation and Edge Position Control

The future of automation holds exciting possibilities, especially for edge position control systems.

7.1 Integration with AI and Machine Learning

The incorporation of artificial intelligence and machine learning into edge position control systems will enhance their capabilities. These technologies can analyze data in real-time, leading to smarter decision-making and improved performance.

7.2 Internet of Things (IoT) Connectivity

As IoT devices become more prevalent, edge position control systems will benefit from enhanced connectivity. This will enable better data sharing and collaboration between systems, leading to improved efficiency.

7.3 Advanced Materials and Sensors

The development of advanced materials and sensors will further enhance the precision of edge position control systems. Innovations in sensor technology will lead to more accurate readings and faster response times.

8. FAQs about Edge Position Control Systems

8.1 What industries benefit most from edge position control systems?

Edge position control systems are particularly beneficial in manufacturing, robotics, aerospace, automotive, and medical device industries.

8.2 How do edge position control systems improve safety?

They improve safety by ensuring that machinery operates within defined parameters, reducing the risk of accidents and operational failures.

8.3 Can edge position control systems be integrated with existing machinery?

Yes, many edge position control systems are designed to be compatible with existing machinery, allowing for seamless integration.

8.4 What are the costs associated with implementing these systems?

Costs can vary depending on the complexity of the system and the specific requirements of the implementation. However, long-term savings often offset initial expenditures.

8.5 How does training impact the success of edge position control systems?

Training is crucial as it ensures employees understand how to operate and maintain the systems, leading to better performance and fewer errors.

9. Conclusion

Edge position control systems are revolutionizing automation by providing enhanced precision, increased efficiency, and significant cost savings across various industries. While challenges exist, the benefits of implementing these advanced systems far outweigh the drawbacks. As technology continues to evolve, the integration of AI, IoT, and advanced sensors will further enhance the capabilities of edge position control systems, making them indispensable in the future of automation. Embracing these innovations not only positions companies for success but also ensures they remain competitive in an increasingly demanding market.

Related information