Understanding the Edge Guide System: A Key Component in Automated Control Systems

Date:

2025-01-26

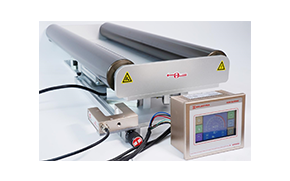

The Edge Guide System is a sophisticated mechanism widely employed in automated control systems, particularly in the manufacturing and processing industries. Essentially, this system plays a crucial role in guiding materials along a predetermined path, ensuring that they maintain consistent alignment and positioning throughout various processes. This capability is especially important in applications such as packaging, cutting, and assembly, where even minor misalignments can lead to significant inefficiencies or product defects.

At its core, the Edge Guide System consists of several key components: sensors, actuators, and control algorithms. Sensors are used to detect the position of the material, providing real-time feedback to the system. This feedback is critical for making instantaneous adjustments, ensuring that the material remains correctly aligned with the desired path. Actuators, on the other hand, are responsible for executing the adjustments based on the sensor data, moving the material accordingly to maintain alignment. The synergy between these components allows for a highly responsive and adaptable system, capable of handling variations in material dimensions and environmental conditions.

One of the major advantages of implementing an Edge Guide System in automated control is the enhancement of operational efficiency. By reducing material misalignment, the system minimizes waste, lowers the risk of equipment damage, and streamlines the overall production process. This not only leads to cost savings for companies but also contributes to higher product quality, as consistently aligned materials are less likely to produce defects.

Moreover, the integration of advanced control algorithms into the Edge Guide System enhances its performance by enabling predictive adjustments. These algorithms analyze data trends over time, allowing the system to anticipate potential misalignments before they occur. This proactive approach significantly reduces downtime and increases throughput, making it an indispensable tool for manufacturers looking to optimize their operations.

In conclusion, the Edge Guide System serves as a cornerstone in the field of automated control systems, offering remarkable benefits such as improved efficiency, reduced waste, and enhanced product quality. As industries increasingly adopt automation to stay competitive, understanding the role and functionality of the Edge Guide System becomes essential for professionals aiming to elevate their operations. By integrating this technology, businesses can not only streamline their processes but also ensure they are well-equipped to meet the demands of an ever-evolving market.

At its core, the Edge Guide System consists of several key components: sensors, actuators, and control algorithms. Sensors are used to detect the position of the material, providing real-time feedback to the system. This feedback is critical for making instantaneous adjustments, ensuring that the material remains correctly aligned with the desired path. Actuators, on the other hand, are responsible for executing the adjustments based on the sensor data, moving the material accordingly to maintain alignment. The synergy between these components allows for a highly responsive and adaptable system, capable of handling variations in material dimensions and environmental conditions.

One of the major advantages of implementing an Edge Guide System in automated control is the enhancement of operational efficiency. By reducing material misalignment, the system minimizes waste, lowers the risk of equipment damage, and streamlines the overall production process. This not only leads to cost savings for companies but also contributes to higher product quality, as consistently aligned materials are less likely to produce defects.

Moreover, the integration of advanced control algorithms into the Edge Guide System enhances its performance by enabling predictive adjustments. These algorithms analyze data trends over time, allowing the system to anticipate potential misalignments before they occur. This proactive approach significantly reduces downtime and increases throughput, making it an indispensable tool for manufacturers looking to optimize their operations.

In conclusion, the Edge Guide System serves as a cornerstone in the field of automated control systems, offering remarkable benefits such as improved efficiency, reduced waste, and enhanced product quality. As industries increasingly adopt automation to stay competitive, understanding the role and functionality of the Edge Guide System becomes essential for professionals aiming to elevate their operations. By integrating this technology, businesses can not only streamline their processes but also ensure they are well-equipped to meet the demands of an ever-evolving market.

Related information