Product Center

Product Overview:

Tension sensor uses principle of strain resistance gauges to detect tension of coi materialsl. Output signal has characteristics of good linearity and fast response. The sensor is sturdy and durable, and can provide high sensitivity even in low tension situations. It can work normally over a wide temperature range without temperature compensation. The entire series of products come in various specifications, sizes, and installation methods, and have been widely used in various roll control equipment and production lines, such as printing machines, slitting machines, rewinding machines, coating machines, etc.

Our tension sensors all use strain gauges, and a single sensor consists of four strain resistors with a resistance value of 350 Ω, forming a Wheatstone full bridge. This greatly improves measurement accuracy and linearity of sensor, making it the perfect choice for your high-speed and high-precision tension measurement!

Selection of tension sensors:

The selection of tension sensors is very important, and incorrect model selection can affect usage and even cause sensor damage. The selection of sensors mainly depends on two aspects: installation type and tension range. Please refer to the following products for installation types. The following mainly introduces the selection of sensor tension values.

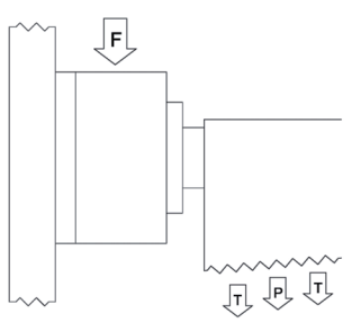

T=Maximum tension value of web (not working tension value)

P=Roller weight

Red dot=direction of resultant force

α=Combined force angle/2

β=Angle between resultant force direction and vertical

direction

F=Resultant tension value (not sensor selection value)

Remark:

- F is resultant force value, sensors are installed on both sides, and a single sensor is subjected to a force of F/2;

- In case of material feeding in Figure 3, if F<P/2; Sensor selection must be greater than P/2;