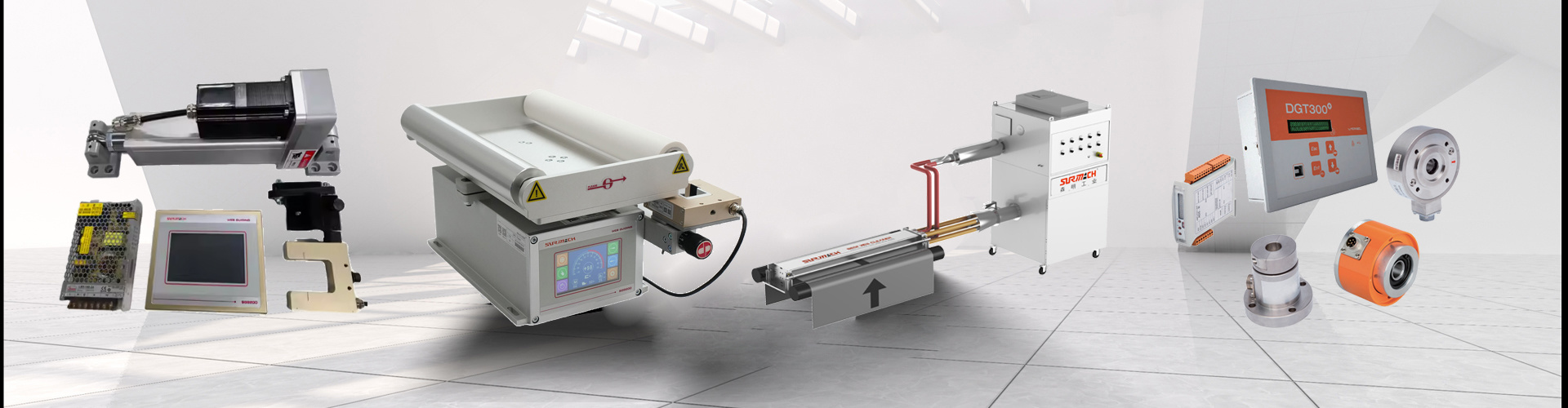

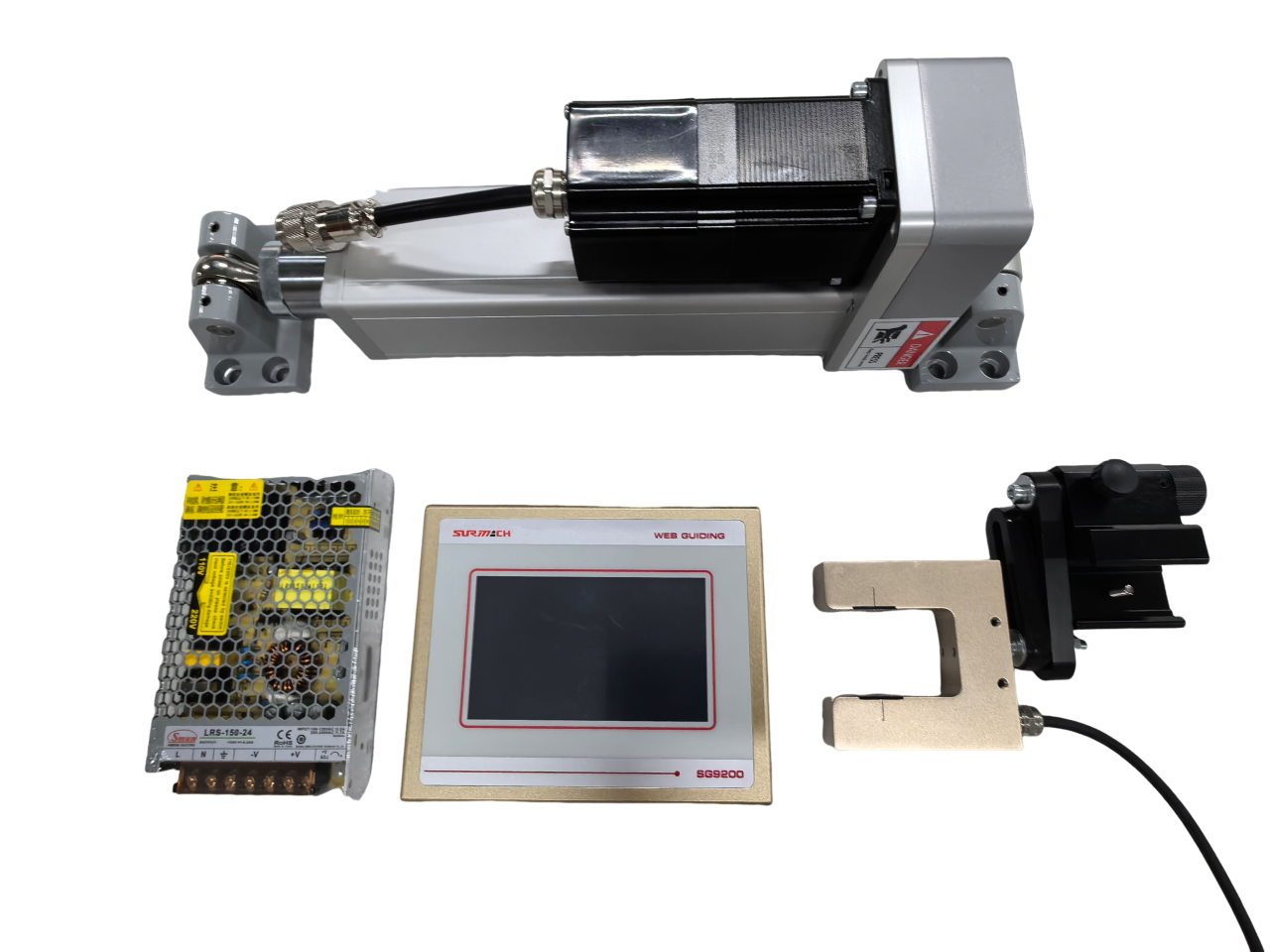

Web Guiding System introduction:

Web Guiding System (also called Web Guide Controller, Web Aligner System, Edge Position Controller, EPC) is a device in using sensor to detect the edge, print line, center of the web to keep the moving web at the right position. Web Guiding Systems are widely used for machineries in film, paper, rubber, textile, metal industries.ect.

Typical web guiding methods:

- Unwinding web guiding: ensure that roll material is always exported from set position during the unwinding process. Design and installation rules: Export roller and discharging mobile frame are integrated. Sensor is installed behind the export roller and fixed separately, close to position of export roller.

- Process web guiding: ensure that web in the process always passes through set position. Design and installation rules: The sensor is installed between the lead-out roller and the pressure roller of guide mechanism, and is fixed separately, close to lead-out roller.

- Rewinding web guiding: Ensure that edges of the roll are neat during rewinding.

Web guiding control method:

EPC-Edge Position Controller

Use one edge guide sensor to detect web edge for edge guiding, also called Edge Guide System.

LPC-Line Position Controller

Use one line follower sensor to detect printing line, contrast edge on the web for guiding, also called Line Guide System, Line Follower Control (LFC).

CPC-Center Position Controller

Use two sensors to detect web for center-line guiding, also called Center Guide System.

Winding and unwinding web guiding systems

Winding and unwinding web guiding systems

Intelligent process web guiding systems