Understanding the Essentials of Web Guiding Equipment in Automation Systems

Date:

2025-01-21

Understanding the Essentials of Web Guiding Equipment in Automation Systems

Table of Contents

- 1. Introduction to Web Guiding Equipment

- 2. Importance of Web Guiding in Automation Systems

- 3. Types of Web Guiding Equipment

- 4. How Web Guiding Equipment Works

- 5. Benefits of Implementing Web Guiding Systems

- 6. Key Applications of Web Guiding Equipment

- 7. Choosing the Right Web Guiding Equipment for Your Needs

- 8. Future Trends in Web Guiding Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Web Guiding Equipment

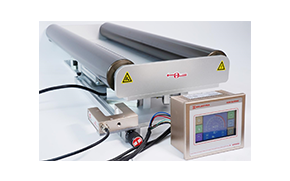

Web guiding equipment plays a pivotal role in modern automation systems, ensuring that materials are correctly aligned during processing. Whether in manufacturing, packaging, or converting industries, web guiding systems are essential for maintaining the integrity of the production line. These systems comprise various components that work together to streamline processes, increase efficiency, and reduce waste.

2. Importance of Web Guiding in Automation Systems

In automation systems, the importance of web guiding cannot be overstated. Misalignment can lead to significant production issues, such as material jams, waste, and increased operational costs. Web guiding equipment ensures that materials remain aligned throughout their journey, contributing to:

- Enhanced Precision: Accurate alignment helps maintain product quality and specifications.

- Reduced Waste: Properly guided materials minimize the risk of defects, thereby reducing waste.

- Increased Efficiency: Streamlined processes lead to higher throughput and reduced downtime.

3. Types of Web Guiding Equipment

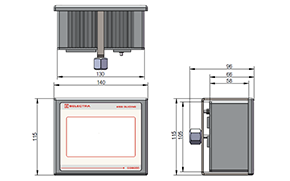

Various types of web guiding equipment are available, each serving distinct purposes. Understanding these types will help organizations select the right equipment for specific applications. The primary categories include:

3.1 Mechanical Guides

Mechanical guides utilize physical components to control the position of the web. These guides are often adjustable and can be used in various applications, making them versatile.

3.2 Optical Guides

Optical guides use sensors and cameras to detect web position. These systems provide real-time feedback and adjustments, ensuring high precision and adaptability.

3.3 Ultrasonic Guides

Ultrasonic guiding systems employ sound waves to monitor the material's position. This technology is beneficial in applications where visual detection is challenging.

4. How Web Guiding Equipment Works

Understanding the functionality of web guiding equipment is essential for optimizing automation systems. Most web guiding systems operate using a combination of:

4.1 Feedback Mechanisms

Web guiding equipment utilizes sensors to collect data about the web's position. This information is crucial for making real-time adjustments.

4.2 Control Systems

Advanced control systems process the data from feedback mechanisms, enabling precise adjustments to be made to maintain alignment.

4.3 Actuators

Actuators are responsible for physically repositioning the web based on the adjustments made by the control system. This could involve moving rollers or other components to guide the web correctly.

5. Benefits of Implementing Web Guiding Systems

Integrating web guiding systems into automation processes provides a myriad of benefits, including:

- Improved Quality Control: Consistent alignment leads to fewer defects and higher-quality products.

- Increased Safety: Reducing jams and misalignments can enhance workplace safety by minimizing potential hazards.

- Cost Savings: By decreasing waste and increasing efficiency, organizations can achieve significant cost savings over time.

6. Key Applications of Web Guiding Equipment

Web guiding equipment finds applications across various industries, including:

6.1 Packaging Industry

In packaging, precise alignment is critical for ensuring that labels, films, and other materials are applied correctly.

6.2 Printing Industry

Printing processes require accurate web control to produce high-quality prints without misregistration or defects.

6.4 Converting Industry

In converting processes, such as cutting or slitting, web guiding systems are vital for maintaining accuracy and efficiency.

7. Choosing the Right Web Guiding Equipment for Your Needs

Selecting the right web guiding equipment is crucial for achieving optimal results. Consider the following factors:

- Material Type: Different materials may require different guiding solutions.

- Application Requirements: Assess the specific needs of your production process to choose the appropriate type of guide.

- Budget Constraints: Balance the need for quality with available financial resources.

8. Future Trends in Web Guiding Technology

As industries continue to embrace automation, web guiding technologies are evolving. Future trends may include:

- Integration with IoT: Enhanced connectivity will allow for better monitoring and data analysis.

- AI and Machine Learning: These technologies will facilitate smarter, adaptive guiding systems that can learn from production patterns.

- Sustainability Initiatives: Advances in materials and technology will aim to reduce waste and enhance environmental sustainability.

9. Frequently Asked Questions

9.1 What is web guiding equipment?

Web guiding equipment refers to systems designed to control the position and alignment of materials during processing in automated production lines.

9.2 How does web guiding equipment improve efficiency?

By ensuring that materials are accurately aligned, web guiding equipment reduces the risk of production issues, leading to smoother operations and higher throughput.

9.3 What types of sensors are used in web guiding equipment?

Common sensors include optical sensors, ultrasonic sensors, and laser sensors, each serving different monitoring and alignment functions.

9.4 Can web guiding systems be integrated with other automation technologies?

Yes, web guiding systems can often be integrated with other automation solutions, enhancing overall production efficiency and data analysis capabilities.

9.5 What industries benefit the most from web guiding equipment?

Industries such as packaging, printing, and converting are among the main sectors that benefit from the precision and efficiency offered by web guiding equipment.

10. Conclusion

In conclusion, the role of web guiding equipment in automation systems is integral to enhancing production efficiency, maintaining quality, and minimizing waste. By understanding the types, benefits, and applications of these systems, organizations can make informed decisions that lead to improved operational success. As technology continues to advance, staying informed about the latest trends in web guiding will be essential for maintaining a competitive edge in the market. Investing in the right web guiding technology is not just about keeping pace with industry standards; it's about setting new benchmarks for quality and efficiency in automated processes.

Related information