Understanding Steering Guide Systems: Enhancing Automation in Control Systems

Date:

2025-01-16

In the realm of automation and control systems, a Steering Guide System is vital for ensuring precision and reliability in operation. These systems are designed to provide directional control and guidance in automated processes, which is particularly crucial in industries that require high levels of accuracy and efficiency. From manufacturing to process control, the implementation of Steering Guide Systems can lead to significant improvements in performance and output quality.

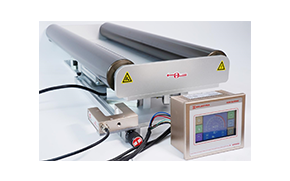

At its core, a Steering Guide System functions by directing equipment or machinery accurately along predetermined paths. This capability is essential for applications such as robotic arms, conveyor systems, and automated guided vehicles (AGVs). By utilizing advanced sensors and control algorithms, Steering Guide Systems can adapt to varying conditions and obstacles, ensuring uninterrupted operation even in dynamic environments.

One of the primary benefits of employing a Steering Guide System is the enhancement of operational efficiency. In automated environments, where speed and precision are paramount, these systems minimize human error and reduce the need for manual intervention. This leads to more streamlined processes, lower operational costs, and increased productivity. Moreover, by integrating Steering Guide Systems into existing workflows, organizations can achieve greater consistency in their output, which is crucial for maintaining quality standards.

Additionally, Steering Guide Systems often incorporate feedback mechanisms that allow for real-time adjustments based on environmental changes or operational demands. This adaptability makes them an essential component in industries where conditions can shift rapidly, such as in manufacturing facilities or logistics centers. The ability to make instantaneous corrections not only improves safety but also enhances the overall reliability of the system.

Another important aspect of Steering Guide Systems is their role in data collection and analysis. Many modern systems are equipped with diagnostic tools that provide valuable insights into system performance and operational efficiency. By analyzing this data, businesses can identify bottlenecks, optimize workflows, and make informed decisions regarding future upgrades or changes.

Furthermore, as industries increasingly move towards automation and smart technology, the integration of Steering Guide Systems is becoming more prevalent. The rise of the Internet of Things (IoT) and Industry 4.0 initiatives emphasizes the need for interconnected systems that can communicate and share data seamlessly. Steering Guide Systems play a crucial role in this transformation by ensuring that automated processes can operate cohesively within a larger network.

In conclusion, the Steering Guide System is a transformative technology within the automation industry, providing critical advantages in precision, efficiency, and adaptability. By leveraging these systems, organizations can enhance their control processes and achieve higher levels of productivity, ultimately leading to a more successful operational strategy. As the demand for automation continues to grow, the significance of Steering Guide Systems will only increase, making them an essential component of modern automated control systems.

At its core, a Steering Guide System functions by directing equipment or machinery accurately along predetermined paths. This capability is essential for applications such as robotic arms, conveyor systems, and automated guided vehicles (AGVs). By utilizing advanced sensors and control algorithms, Steering Guide Systems can adapt to varying conditions and obstacles, ensuring uninterrupted operation even in dynamic environments.

One of the primary benefits of employing a Steering Guide System is the enhancement of operational efficiency. In automated environments, where speed and precision are paramount, these systems minimize human error and reduce the need for manual intervention. This leads to more streamlined processes, lower operational costs, and increased productivity. Moreover, by integrating Steering Guide Systems into existing workflows, organizations can achieve greater consistency in their output, which is crucial for maintaining quality standards.

Additionally, Steering Guide Systems often incorporate feedback mechanisms that allow for real-time adjustments based on environmental changes or operational demands. This adaptability makes them an essential component in industries where conditions can shift rapidly, such as in manufacturing facilities or logistics centers. The ability to make instantaneous corrections not only improves safety but also enhances the overall reliability of the system.

Another important aspect of Steering Guide Systems is their role in data collection and analysis. Many modern systems are equipped with diagnostic tools that provide valuable insights into system performance and operational efficiency. By analyzing this data, businesses can identify bottlenecks, optimize workflows, and make informed decisions regarding future upgrades or changes.

Furthermore, as industries increasingly move towards automation and smart technology, the integration of Steering Guide Systems is becoming more prevalent. The rise of the Internet of Things (IoT) and Industry 4.0 initiatives emphasizes the need for interconnected systems that can communicate and share data seamlessly. Steering Guide Systems play a crucial role in this transformation by ensuring that automated processes can operate cohesively within a larger network.

In conclusion, the Steering Guide System is a transformative technology within the automation industry, providing critical advantages in precision, efficiency, and adaptability. By leveraging these systems, organizations can enhance their control processes and achieve higher levels of productivity, ultimately leading to a more successful operational strategy. As the demand for automation continues to grow, the significance of Steering Guide Systems will only increase, making them an essential component of modern automated control systems.

Related information