Detail

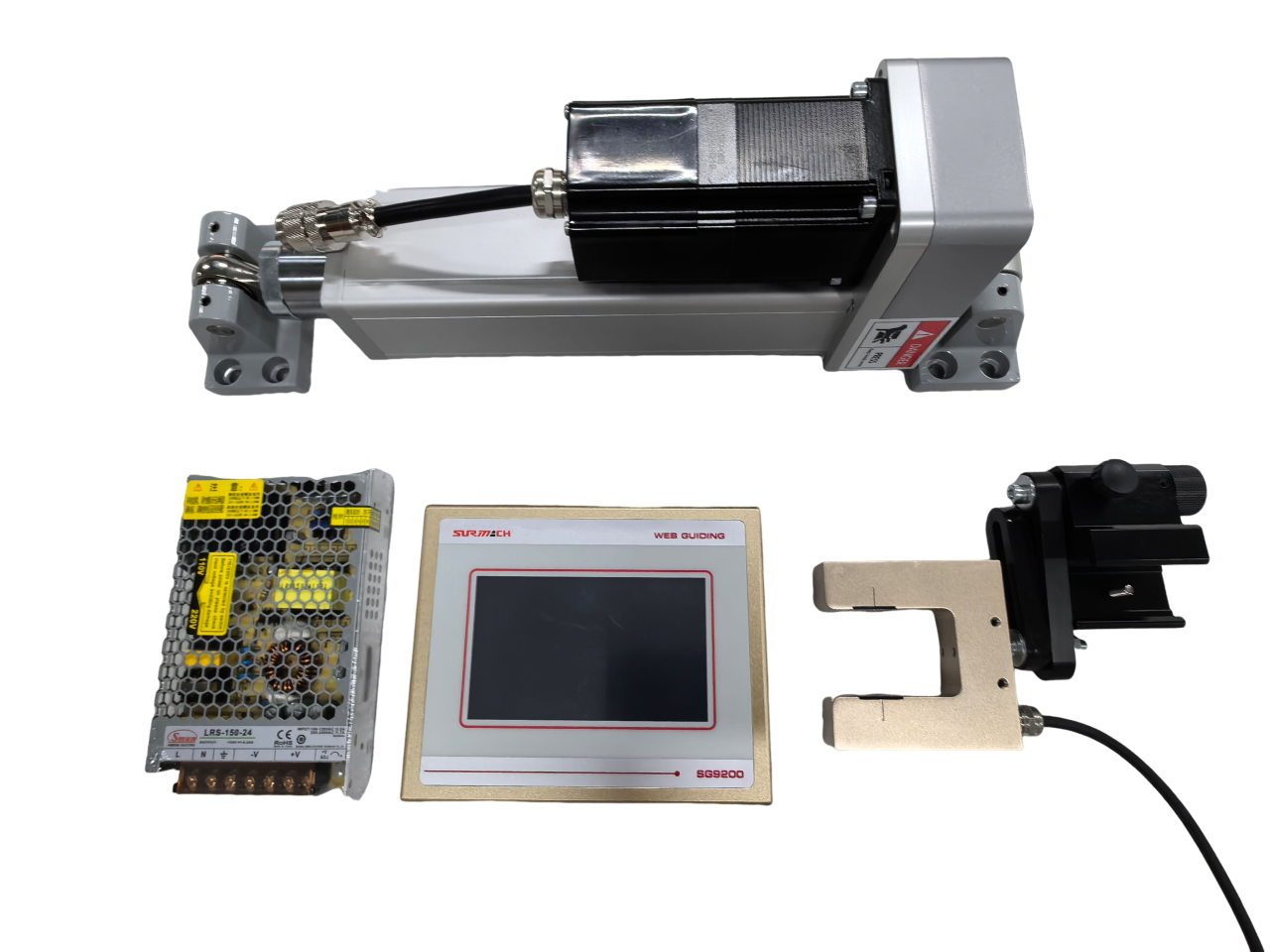

Winding and unwinding intelligent web guiding device

Web Guiding System introduction:

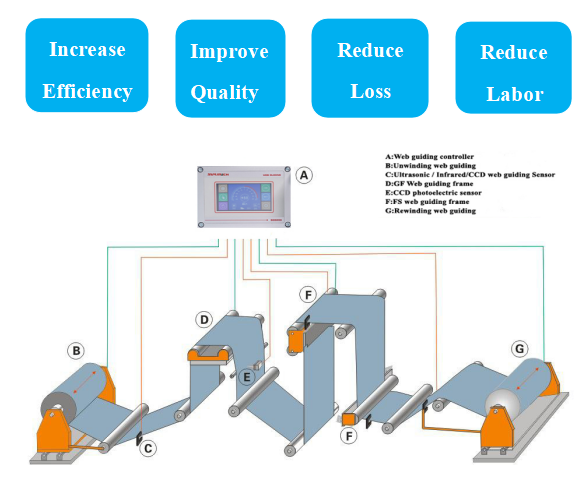

Web Guiding System (also called Web Guide Controller, Web Aligner System, Edge Position Controller, EPC) is a device in using sensor to detect the edge, print line, center of the web to keep the moving web at the right position. Web Guiding Systems are widely used for machineries in film, paper, rubber, textile, metal industries.ect.

Web guiding system is a closed-loop automatic control system composed of guiding controllers, guiding sensors, drivers, or guiding frames and other components. Guiding sensor detects position of material edges or lines, and this position information is converted into electrical signals and transmitted to guiding controller. Guiding controller compares signal with set position signal, outputs corresponding adjustment signal based on deviation, drives guiding electric actuator to perform guiding actions, and achieves purpose of correcting material offset.

Controller, Sensor and actuators model for web guide: Customers can choose according to actual materials and applications

Web guiding system application:

Web guiding controller

LPC-6 digital screen integrated web guiding controller

Product description:

Powerful performance: The system adopts a 32-bit ARM high-performance processor

Touch screen interface: Real time display of various operation statuses, more user-friendly

Easy to use: The main interface can complete operations, fully considering the convenience of operation

Intelligent PID: Self applicable PID program design, ensuring efficient and high-precision correction

Protection circuit: With comprehensive anti-interference technology, various electromagnetic interferences can be effectively eliminated

One machine with multiple functions: supporting edge alignment, centering, CCD line following edge tracking, and double-layer material tracking functions

Fully functional: suitable for various application scenarios - edge detection, centering, line following, and following correction. With comprehensive auxiliary functions

Stable quality: The system is equipped with built-in overcurrent, overvoltage, and overload protection functions, ensuring the long-term reliable operation of the correction system

External dimension and installation diagram:

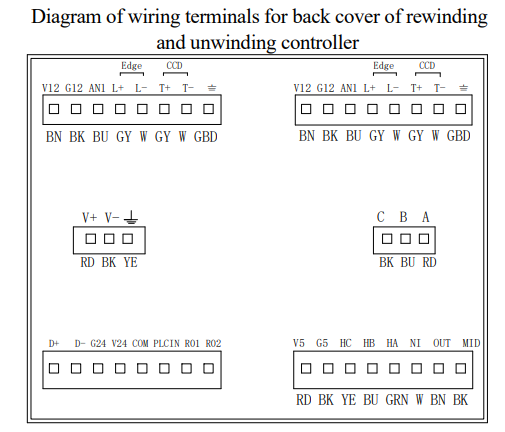

Electrical wiring diagram:

Product parameter

|

Control accuracy |

Rated power |

Web guiding load |

Protection level |

Ambient temperature |

Work voltage |

Air humidity |

|

±0.1mm |

240w |

0~10 Ton |

Ip67 |

-10~+60℃ |

24CDV |

0~90% |

Note: Above web guiding accuracy is an ideal state accuracy, and it is necessary to ensure good working conditions, including tension stability, guide roller balance, equipment strength, incoming material deviation, and guiding parameter settings.

Web guiding sensor

TUS2 ultrasonic web guiding sensor

Product Description:

Detection accuracy up to 0.01mm

Accurate signal detection and strong anti-interference ability

Equipped with environmental detection and correction functions

Various material edges can be detected

Customizable wide width sensors

Application:

Used for non-contact scanning of roll edges

|

Coil materials type |

Transparent material |

Opaque materials |

Foil |

Metal sheet |

Paper |

Photosensitive materials |

Non-woven fabric |

Textiles |

Mesh fabric |

|

Ultrasonic web guiding sensor |

▇ |

▇ |

▇ |

▇ |

▇ |

▇ |

|

|

|

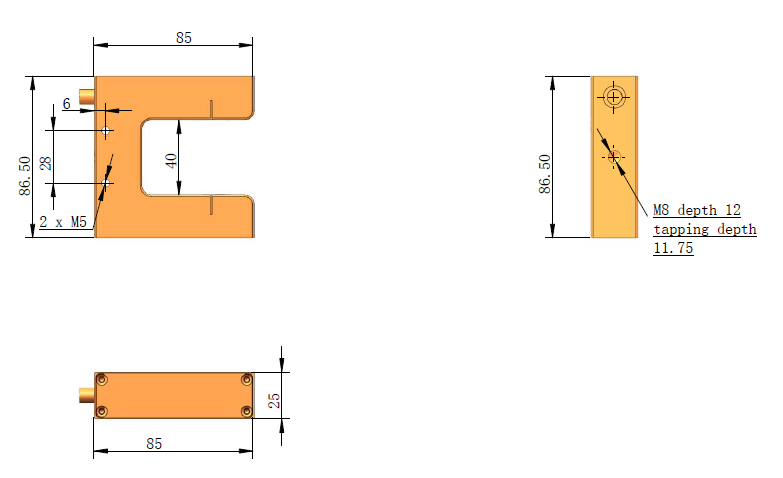

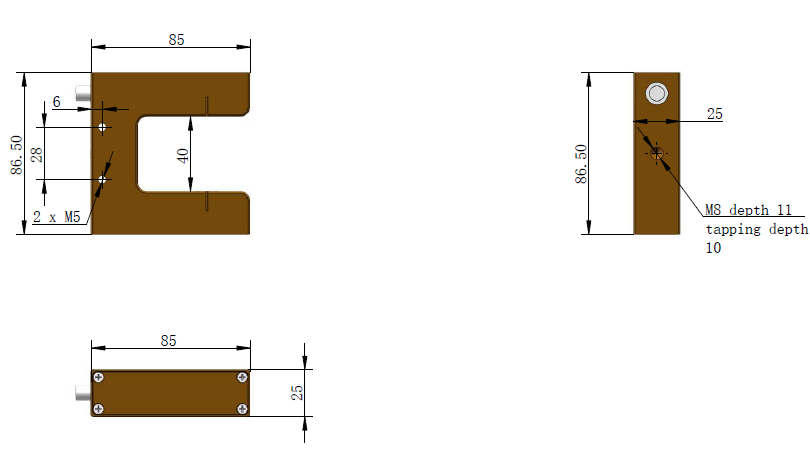

External dimension diagram:

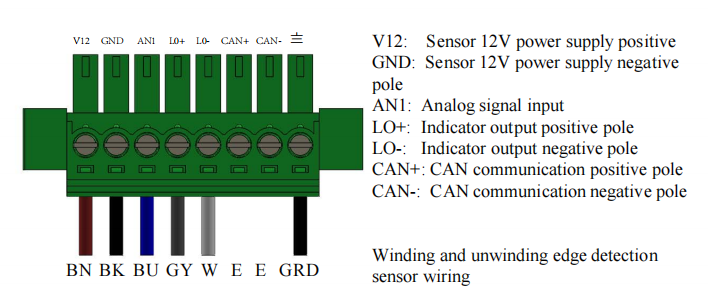

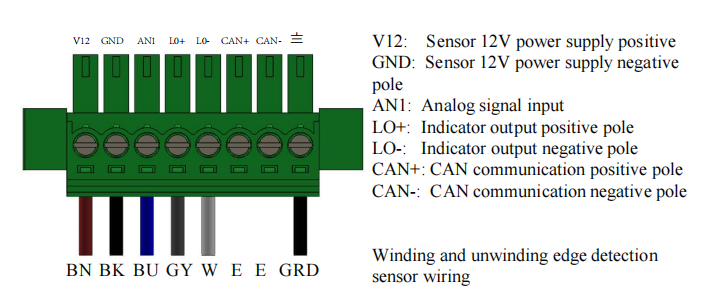

Electrical wiring diagram:

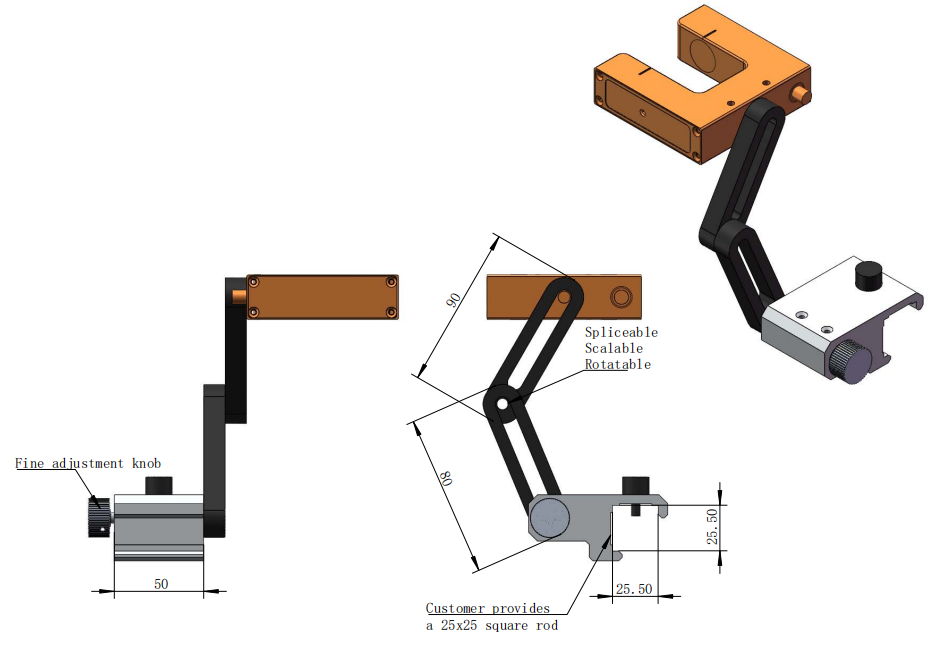

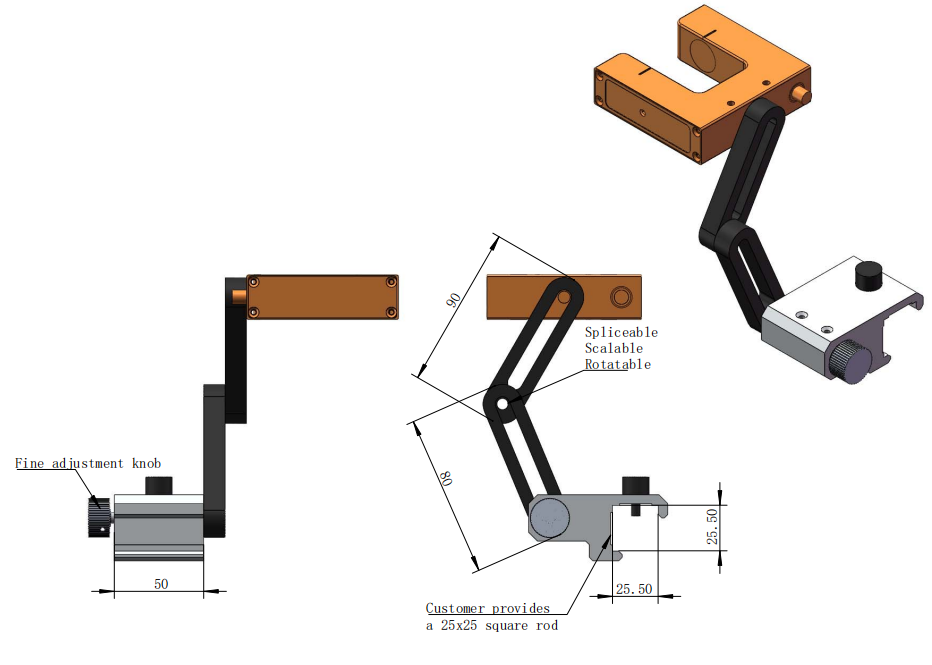

Installation diagram:

Product parameter

|

Detection range |

Resolution ratio |

Output signal |

Power supply |

U-shaped opening spacing |

Working temperature range |

Protection grade |

|

6mm |

0.01mm |

0-5V |

12VDC/0.1A |

40mm |

-10℃~+50℃ |

IP54 |

TIR2 infrared web guiding sensor

Product Description:

Detection accuracy up to 0.01mm

Accurate signal detection and strong anti-interference ability

Equipped with environmental detection and correction functions

Various material edges can be detected

Customizable wide width sensors

Application:

Used for non-contact scanning of roll edges

|

Coil materials type |

Transp arent material |

Photosen sitive materials |

Opaque materials |

Foil |

Metal sheet |

Paper |

Non-woven fabric |

Textiles |

Mesh fabric |

|

Infrared web guiding Sensor |

|

|

▇ |

▇ |

▇ |

▇ |

▇ |

▇ |

▇ |

External dimension diagram:

Electrical wiring diagram:

Installation diagram:

Product parameter

|

Detection range |

Resolution ratio |

Output signal |

Power supply |

U-shaped opening spacing |

Working temperature range |

Protection grade |

|

8mm |

0.01mm |

0-5V |

12VDC/0.1A |

40mm |

-10℃~+50℃ |

IP54 |

CCD sensors can be selected as needed:

CLS60 CCD web guiding sensor:

Product Description:

High-speed CCD sensor camera

One-click calibration, automatically identify and store target characteristics

Advanced algorithm ensures stable tracking and eliminates interference signals

Accurately identify low-contrast, reflective, holographic, and transparent materials

Laser-assisted positioning, real-time offset display

Target lost alarm output

Process parameter backup and recall

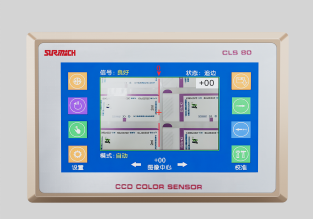

CLS80 Color CCD web guiding Sensor:

CLS80-1 integrated screen: CLS80-2 Rotating Screen:

Product description:

High speed, high-resolution color CCD image sensor

Perform optical scanning using a CCD line or surface scanning camera,accurately identify low contrast, reflective, holographic, and transparent materials

Automatically adjust exposure to different environmental conditions

Overall or additional optical options

Real time image display, clear tracking effect at a glance

One click calibration, automatically identifying and storing target features

Advanced algorithms ensure stable tracking and eliminate interference signals

Backup and retrieval of process parameters

Web guiding driver

|

Model no |

Route or distance (mm) |

Maximum speed(mm/s) |

Rated load(kg)

|

Applicable methods |

|

ACT-80A |

±40 |

35 |

600 |

Medium guide frame, winding and unwinding |

|

ACT-80B |

±40 |

35 |

1000 |

Medium guide frame, winding and unwinding |

|

ACT-100-A |

±50 |

50 |

1500 |

Large guide frame, winding and unwinding |

|

ACT-150-A |

±75 |

50 |

1500 |

Winding and unwinding |

|

ACT-200-A |

±100 |

50 |

2000 |

Winding and unwinding |

|

ACT-100-B |

±50 |

40 |

3500 |

Winding and unwinding |

|

ACT-150-B |

±75 |

40 |

3500 |

Winding and unwinding |

|

ACT-200-B |

±100 |

40 |

3500 |

Winding and unwinding |

|

ACT-100-C |

±50 |

36 |

5000 |

Winding and unwinding |

|

ACT-150-C |

±75 |

20 |

5000 |

Winding and unwinding |

|

ACT-200-C |

±100 |

30 |

5000 |

Winding and unwinding |

|

ACT-150-D |

±75 |

20 |

10000 |

Winding and unwinding |

|

ACT-200-D |

±100 |

20 |

10000 |

Winding and unwinding |

ACT-80A/B driver external dimension diagram:

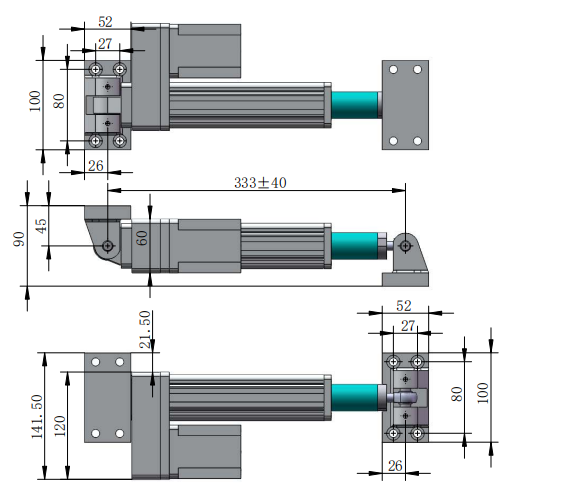

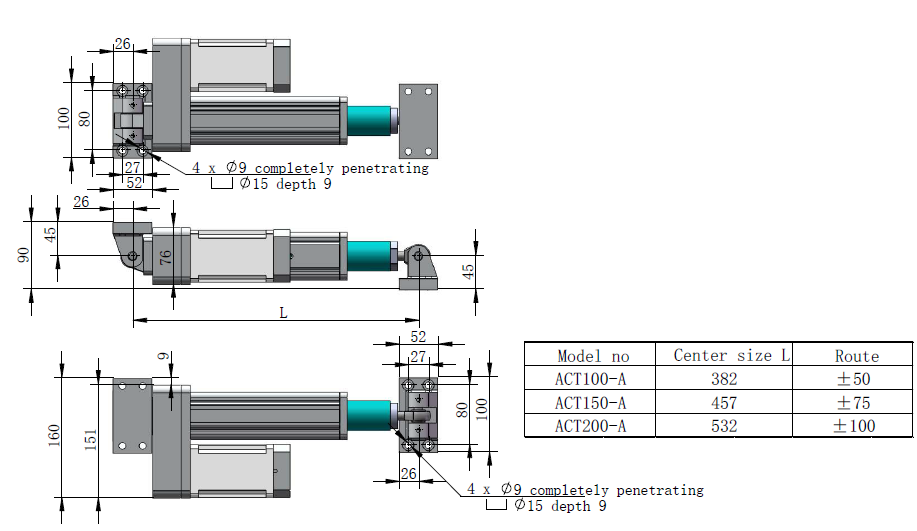

ACT-100/150/200-A driver external dimension diagram:

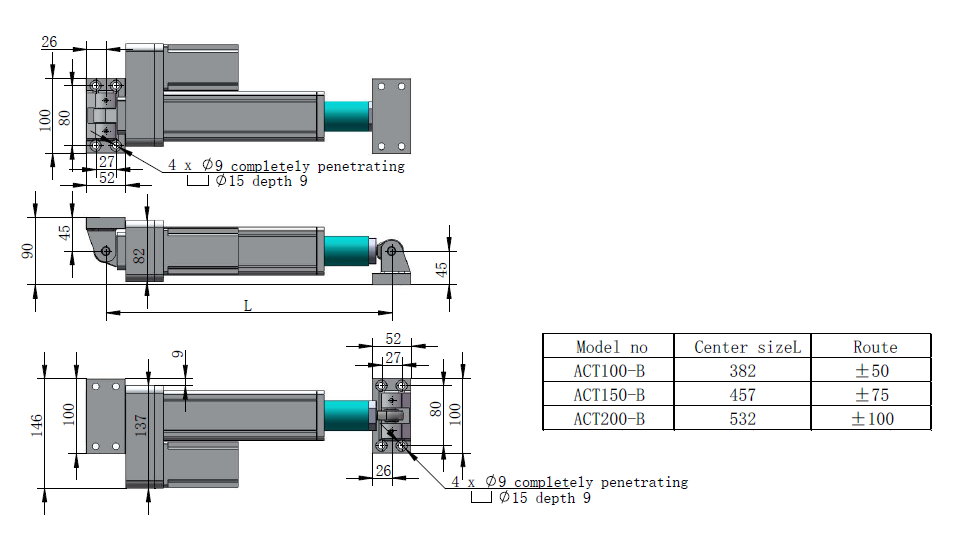

ACT-100/150/200-B driver external dimension diagram:

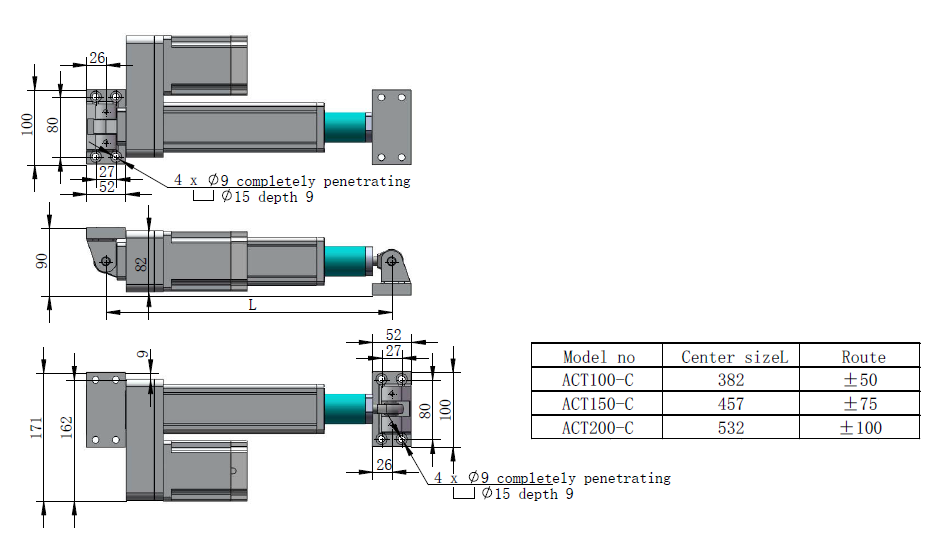

ACT-100/150/200-C driver external dimension diagram:

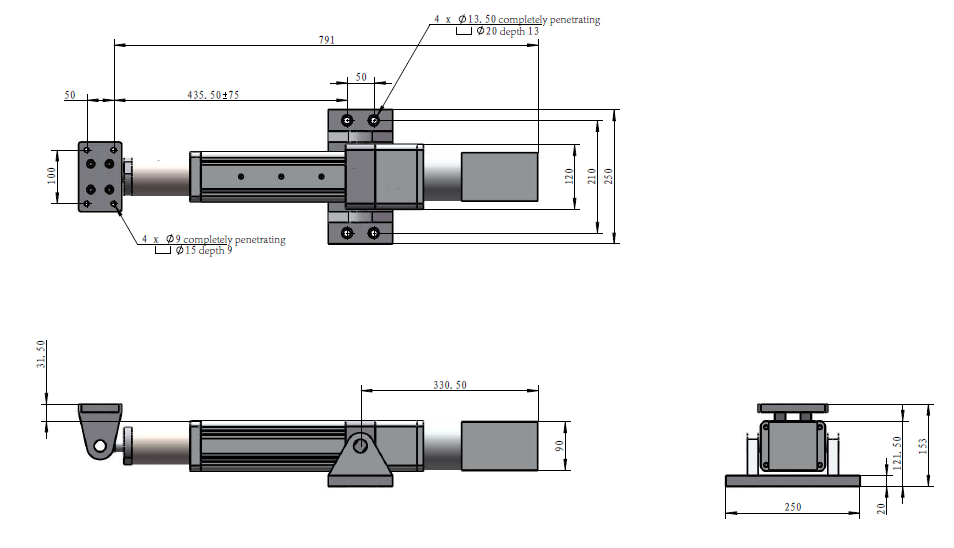

ACT-150-D driver external dimension diagram:

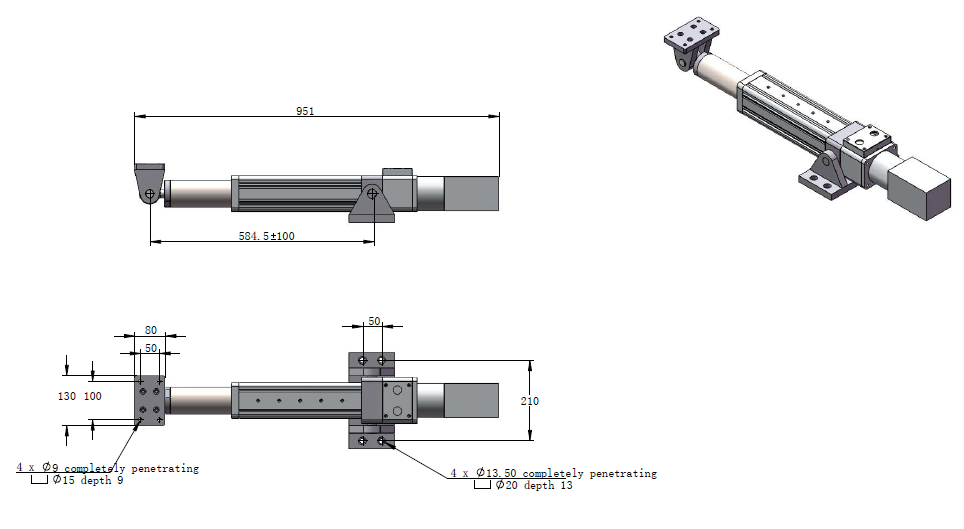

ACT-200-D driver external dimension diagram:

HOT PRODUCTS

Product Enquiry