Enhancing Precision: The Role of Axial Tension Sensors in Modern Electronics

Date:

2024-05-15

**Introduction**

In the ever-evolving world of electronics, precision and accuracy are crucial factors that can make or break the success of a device or system. One technology that is playing a significant role in enhancing precision in modern electronics is axial tension sensors. These sensors are revolutionizing the way electronic devices are designed and operated, providing engineers with valuable data that can help improve performance and efficiency. In this article, we will explore the role of axial tension sensors in modern electronics and how they are changing the game in terms of precision and accuracy.

**What are Axial Tension Sensors?**

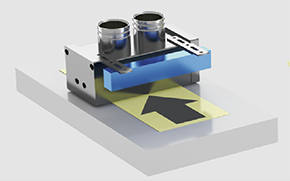

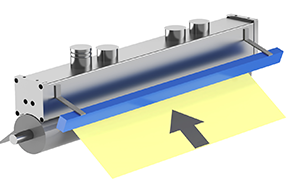

Axial tension sensors are devices that are used to measure the tension or strain applied to an object along a specific axis. These sensors are commonly used in a wide range of applications, including automotive, aerospace, robotics, and medical devices. By providing real-time data on the tension or strain applied to an object, axial tension sensors can help engineers optimize the performance of their designs and ensure that they meet the required specifications.

**The Benefits of Axial Tension Sensors**

One of the key benefits of using axial tension sensors in modern electronics is the enhanced precision and accuracy they provide. By monitoring the tension or strain applied to an object in real-time, engineers can make adjustments to their designs to ensure optimal performance. This can result in improved efficiency, reliability, and overall product quality.

**Applications of Axial Tension Sensors**

Axial tension sensors are used in a wide variety of applications in modern electronics. In the automotive industry, these sensors are used to measure the tension in safety belts, airbag deployment systems, and suspension components. In the aerospace industry, axial tension sensors are used to monitor the tension in aircraft wings, landing gear, and other critical components. In the medical device industry, these sensors are used to measure the tension in surgical instruments, robotic systems, and patient monitoring devices.

**How Axial Tension Sensors are Changing the Game**

The use of axial tension sensors in modern electronics is revolutionizing the way engineers design and operate electronic devices. By providing real-time data on the tension or strain applied to an object, these sensors are enabling engineers to make more informed decisions about their designs and optimize performance. This level of precision and accuracy was previously unattainable, but with the advancement of axial tension sensor technology, engineers can now achieve levels of precision that were once thought impossible.

**FAQs**

1. How do axial tension sensors work?

2. What are the key benefits of using axial tension sensors in modern electronics?

3. What are some common applications of axial tension sensors?

4. How are axial tension sensors revolutionizing the world of modern electronics?

5. Are axial tension sensors easy to install and calibrate?

**Conclusion**

In conclusion, axial tension sensors are playing a crucial role in enhancing precision and accuracy in modern electronics. By providing real-time data on the tension or strain applied to an object, these sensors are enabling engineers to optimize the performance of their designs and ensure that they meet the required specifications. As technology continues to advance, we can expect axial tension sensors to become even more integral to the world of modern electronics, revolutionizing the way electronic devices are designed and operated.

In the ever-evolving world of electronics, precision and accuracy are crucial factors that can make or break the success of a device or system. One technology that is playing a significant role in enhancing precision in modern electronics is axial tension sensors. These sensors are revolutionizing the way electronic devices are designed and operated, providing engineers with valuable data that can help improve performance and efficiency. In this article, we will explore the role of axial tension sensors in modern electronics and how they are changing the game in terms of precision and accuracy.

**What are Axial Tension Sensors?**

Axial tension sensors are devices that are used to measure the tension or strain applied to an object along a specific axis. These sensors are commonly used in a wide range of applications, including automotive, aerospace, robotics, and medical devices. By providing real-time data on the tension or strain applied to an object, axial tension sensors can help engineers optimize the performance of their designs and ensure that they meet the required specifications.

**The Benefits of Axial Tension Sensors**

One of the key benefits of using axial tension sensors in modern electronics is the enhanced precision and accuracy they provide. By monitoring the tension or strain applied to an object in real-time, engineers can make adjustments to their designs to ensure optimal performance. This can result in improved efficiency, reliability, and overall product quality.

**Applications of Axial Tension Sensors**

Axial tension sensors are used in a wide variety of applications in modern electronics. In the automotive industry, these sensors are used to measure the tension in safety belts, airbag deployment systems, and suspension components. In the aerospace industry, axial tension sensors are used to monitor the tension in aircraft wings, landing gear, and other critical components. In the medical device industry, these sensors are used to measure the tension in surgical instruments, robotic systems, and patient monitoring devices.

**How Axial Tension Sensors are Changing the Game**

The use of axial tension sensors in modern electronics is revolutionizing the way engineers design and operate electronic devices. By providing real-time data on the tension or strain applied to an object, these sensors are enabling engineers to make more informed decisions about their designs and optimize performance. This level of precision and accuracy was previously unattainable, but with the advancement of axial tension sensor technology, engineers can now achieve levels of precision that were once thought impossible.

**FAQs**

1. How do axial tension sensors work?

2. What are the key benefits of using axial tension sensors in modern electronics?

3. What are some common applications of axial tension sensors?

4. How are axial tension sensors revolutionizing the world of modern electronics?

5. Are axial tension sensors easy to install and calibrate?

**Conclusion**

In conclusion, axial tension sensors are playing a crucial role in enhancing precision and accuracy in modern electronics. By providing real-time data on the tension or strain applied to an object, these sensors are enabling engineers to optimize the performance of their designs and ensure that they meet the required specifications. As technology continues to advance, we can expect axial tension sensors to become even more integral to the world of modern electronics, revolutionizing the way electronic devices are designed and operated.

Related information