Mastering Web Guide Control in Automated Instrumentation Equipment

Date:

2024-05-20

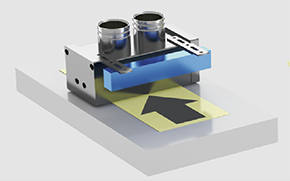

Web guide control is a crucial aspect of automated instrumentation equipment, especially in the field of control instruments. It allows for precise alignment and positioning of materials such as webs, films, or other substrates, ensuring accurate and consistent results in various industrial applications.

To effectively utilize web guide control in your automated instrumentation equipment, consider the following key points:

1. Understanding the Basics: Familiarize yourself with the principles of web guide control, including how it works, common applications, and the benefits it offers in enhancing the performance of your control instrument.

2. Calibration and Setup: Proper calibration and setup of your web guide control system are essential for achieving accurate and reliable results. Ensure that your equipment is calibrated correctly and aligned with the material being processed.

3. Troubleshooting: Be prepared to troubleshoot common issues that may arise with web guide control, such as misalignment, sensor malfunctions, or drift. Having a thorough understanding of the system will help you identify and address issues promptly.

4. Maintenance and Care: Regular maintenance of your web guide control system is crucial to ensure optimal performance and longevity. Keep your equipment clean, inspect for wear and tear, and follow manufacturer recommendations for upkeep.

5. Continuous Improvement: Stay updated on the latest advancements in web guide control technology and techniques. Implementing new strategies and technologies can help you enhance the efficiency and accuracy of your automated instrumentation equipment.

By mastering web guide control in your automated instrumentation equipment, you can optimize performance, increase productivity, and achieve superior results in your industrial processes. Stay informed, proactive, and diligent in managing your control instrument to unlock its full potential.

Related information