Intelligent all-in-one machine

Categorisation: Web guide

Detail

Intelligent all-in-one machine web guiding device is a device used to correct material deviation and is widely used in various industrial production fields. It usually adopts detection devices such as photoelectric sensors or ultrasonic sensors to monitor the position of materials in real time. When the material is offset, the sensor will detect the offset signal and transmit the signal to the controller. The controller calculates the adjustment amount required for correction according to the offset signal, and then adjusts the material through the driving device to bring it back to the correct position.

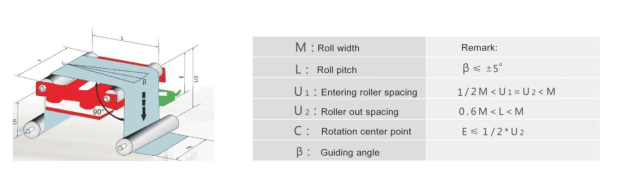

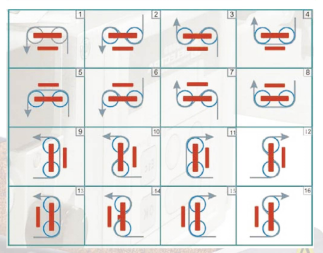

Schematic diagram:

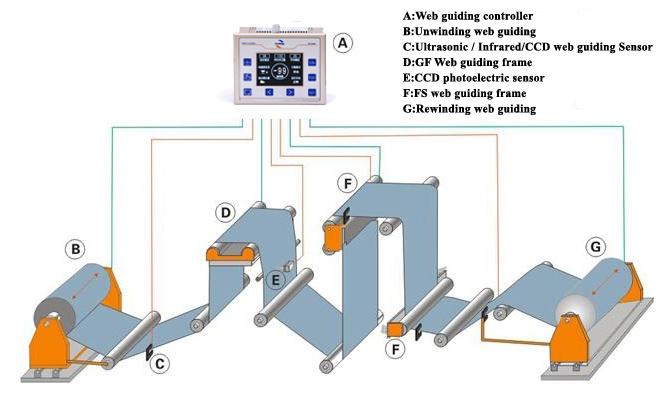

Wiring diagram:

Web guiding system application:

Product Description:

Intelligent adaptive PID program design, high-precision correction.

Intelligent judgment and adjustment of driver polarity.

High performance 32-bit ARM processor.

Touch screen operation panel, more user-friendly.

Edge alignment, centering, CCD line following, double-layer material tracking.

PLC interface, limit alarm, reverse stop, remote manual/automatic switching.

Complete overcurrent, overvoltage, and overload protection functions.

Comprehensive anti-interference technology and circuit design.

Edge inspection all-in-one machine CCD all-in-one machine

Product parameter

|

GF-S/Model no |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

|

Roll diameter(mm) |

50 |

50 |

50 |

50/60/75 |

50/60/75 |

50/60/75 |

50/60/75 |

50/60/75 |

50/60/75 |

50/60/75 |

50/60/75 |

|

Roll width(mm) |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

|

Maximum Roll pitch(mm) |

150 |

200 |

250 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Maximum tension |

800N |

1500N |

|||||||||

|

Guiding speed |

Maximum speed 25mm/s |

||||||||||

|

Route& βAngle |

±25mm&≤±5°(Special requirements can be specified) |

||||||||||

|

Supply powder |

24V DC,6A-10A |

||||||||||

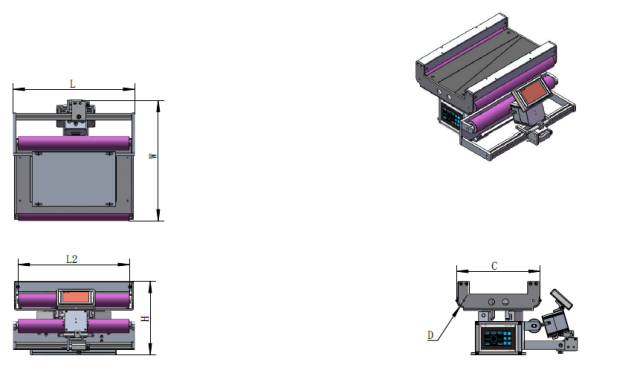

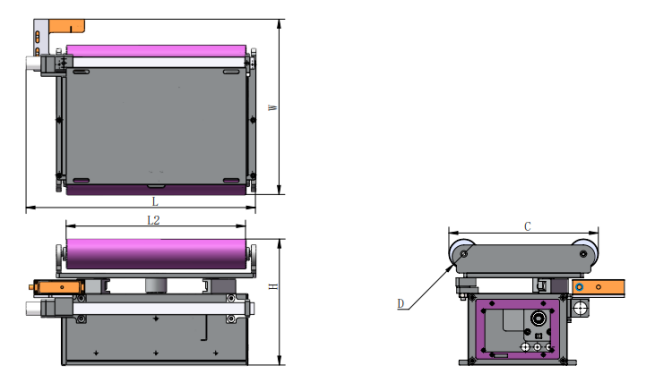

Dimension diagram:

CCD all-in-one machine:

Edge inspection all-in-one machine:

web guide

web guiding

web guide system

web guide control

web guiding system

Web Guides

Web Guide Controller

Guiding Systems

HOT PRODUCTS

Product Enquiry