Understanding Idler Type Tension Sensors in the Electronic Components Industry

Date:

2024-05-30

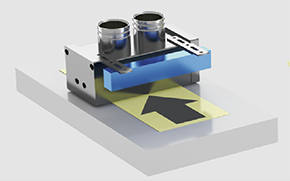

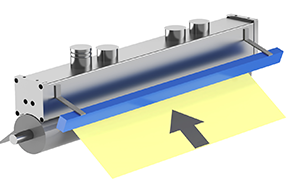

Idler type tension sensors play a crucial role in the electronic components industry, specifically in the realm of sensors. These sensors are designed to measure and monitor tension in various applications, providing valuable data that can help optimize processes and ensure product quality.

One of the key features of idler type tension sensors is their ability to accurately measure tension without direct contact with the material being monitored. This non-contact measurement method helps prevent damage to the material and allows for continuous monitoring without interrupting the production process.

These sensors are commonly used in a wide range of applications, including paper manufacturing, printing, textile production, and wire and cable processing. By accurately measuring tension, idler type tension sensors can help improve product quality, prevent breakages, and reduce downtime.

In addition to their monitoring capabilities, idler type tension sensors also offer benefits such as easy installation, low maintenance requirements, and compatibility with various types of materials. This versatility makes them a popular choice for manufacturers looking to enhance their production processes.

Overall, idler type tension sensors are essential tools for ensuring optimal performance and quality in the electronic components industry. By understanding how these sensors work and their various applications, manufacturers can make informed decisions to improve efficiency and productivity.

One of the key features of idler type tension sensors is their ability to accurately measure tension without direct contact with the material being monitored. This non-contact measurement method helps prevent damage to the material and allows for continuous monitoring without interrupting the production process.

These sensors are commonly used in a wide range of applications, including paper manufacturing, printing, textile production, and wire and cable processing. By accurately measuring tension, idler type tension sensors can help improve product quality, prevent breakages, and reduce downtime.

In addition to their monitoring capabilities, idler type tension sensors also offer benefits such as easy installation, low maintenance requirements, and compatibility with various types of materials. This versatility makes them a popular choice for manufacturers looking to enhance their production processes.

Overall, idler type tension sensors are essential tools for ensuring optimal performance and quality in the electronic components industry. By understanding how these sensors work and their various applications, manufacturers can make informed decisions to improve efficiency and productivity.

Related information