Product Center

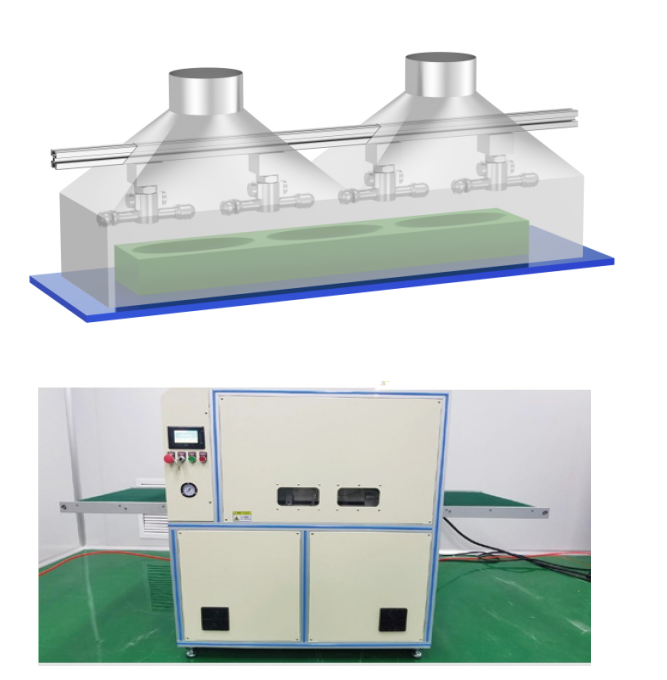

High pressure cyclone cleaning system

Categorisation: High pressure cyclone cleaning system

Detail

Our surface cleaning systems include the following product lines:

Dry ultrasonic dust removal system (VUV, UVU, VUV):

Curved surface, flat surface, edge, profiling

Double sided suspended dust removal system (VPV, VUV, UVU):

Highssure air, ultrasonic

High pressure cyclone dust removal system:

Conveying device, automatic loading and unloading (customized)

Brush roller ultrasonic dust removal system

Cleaner:

High-pressure cyclone surface cleaning system is designed to meet requirements of uneven and multi-dimensional dust removal for products. The system consists of a high-pressure cyclone nozzle, negative pressure suction unit, electrostatic removal device, and negative pressure dust collection device. When the product passes through surface cleaning unit, static electricity is first removed, and the nozzle rotates at high speed after being connected to compressed air. High pressure and intermittent jets are sprayed on the surface of the product. With alternating pressure changes and multiple blowing, the dust is blown up and sucked into the dust collection room by negative pressure. This dust removal system can customize various loading and unloading and conveying devices according to customer requirements. The entire system is equipped with a touch screen, PLC, and various sensors to achieve various automatic control and online control functions. It can be combined with mechanical arms or servo drives and slide modules to achieve unmanned and fully automatic loading and unloading, reducing manual labor and significantly improving production efficiency.

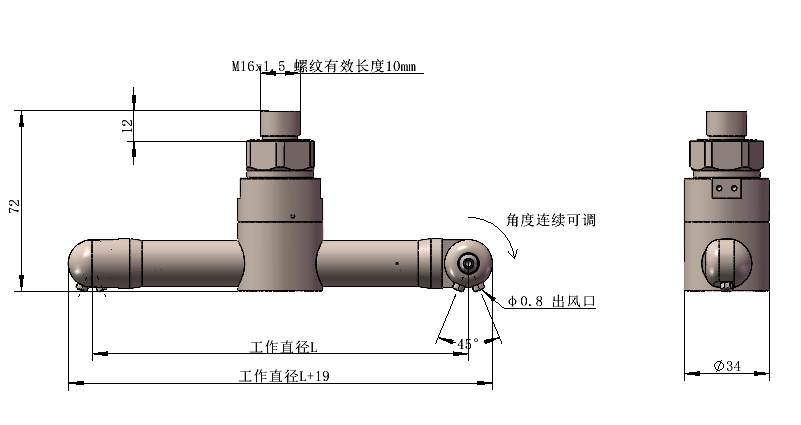

Product specification

|

Product type |

Product model |

Diameter |

|

high-pressure cyclone surface cleaning unit |

ARH120 |

120 |

|

ARH150 |

150 |

|

|

ARH180 |

180 |

|

|

Product conveyor line |

Optional |

|

Dimensional drawing:

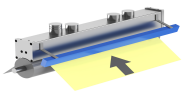

Application:

Suitable for uneven and multi-faceted dust removal, various loading and unloading and conveying devices can be customized according to customer requirements. The entire system is equipped with a touch screen, PLC, and various sensors to achieve various automatic control and online control functions. It can be integrated with robotic arms or servo drives and slide table modules to achieve unmanned and fully automatic loading and unloading, reducing manual labor and significantly improving production efficiency.

Cleaner types:

Web arc cleaner

Cleaning Host:

Efficient fan, filter cartridge type high-efficiency filter, high-quality filter element

Pulse back blowing dust cleaning system

Control system adopts touch screen, intelligent dust removal controller, various pressure and differential pressure sensors

Details

HOT PRODUCTS

Product Enquiry