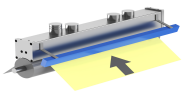

Edge slitting cleaning system

Categorisation: Edge slitting cleaning system

Detail

Our surface cleaning systems include the following product lines:

Dry ultrasonic dust removal system (VUV, UVU, VUV):

Curved surface, flat surface, edge, profiling

Double sided suspended dust removal system (VPV, VUV, UVU):

Highssure air, ultrasonic

High pressure cyclone dust removal system:

Conveying device, automatic loading and unloading (customized)

Brush roller ultrasonic dust removal system

Cleaner:

After material cutting, material debris and impurities will be generated at the cutting blade and material edge positions, resulting in a decrease in the yield rate. Our edge surface cleaning technology integrates our patented ultrasonic dust removal technology, utilizing high-pressure wind and ultrasonic vibration to effectively solve common problems such as inability to blow and suction. The surface cleaning head has a compact volume, simple installation, low energy consumption, low cost, and obvious surface cleaning effect.

Product specification

|

Product type |

Model no |

Surface cleaning range |

Positive pressure air source |

Negative pressure |

Ultrasonic |

Impurity size removed |

|

Compressed air ultrasonic edge surface cleaning unit |

SEC-06-5mm |

5mm can be customized |

0.2-0.7Mpa |

-2-8Kpa |

25-52KHZ |

》3um |

|

High pressure wind ultrasonic edge surface cleaning unit |

SEC-10-5mm |

5mm can be customized |

Fan supply |

-1-5Kpa |

25-52KHZ |

》5um |

Application:

Suitable for removing material debris and impurities generated by the cutting blade and material edge position after product slitting.

Cleaner types:

Web arc cleaner

Cleaning Host:

Efficient fan, filter cartridge type high-efficiency filter, high-quality filter element

Pulse back blowing dust cleaning system

Control system adopts touch screen, intelligent dust removal controller, various pressure and differential pressure sensors

Details

HOT PRODUCTS

Product Enquiry